the problem

So, someone gave me about tonne of apples for “personal use”. I really need to get better at saying no to free stuff. I left maybe 300kg behind (showing huge restraint right there) so only ended up with a meagre ~900kg of apples… And no equipment to deal with them.

First of all, I blasted up the apples with a sharpened paint / mortar mixer on a grunty drill (highly effective, cheaper than dedicated equipment) and stuck the pulp in sacks in a couple of chest freezers to buy myself some sea room while I build a press. This lets me smash (“scratter”, I guess) apples in about 50-60kg batches, and at the same time I added pectinase to get me better extraction down the line.

The pulp went into plastic sacks and got frozen (took forever to freeze in the middle) and, having made an enormous, icy, apple flavoured problem for myself, I started to think about a press… We’re not going to dwell on how hard it was to get the sacks back out of the freezer, that chapter is best forgotten.

Materials, goals…

I don’t really drink much cider so I wanted to do this on a shoestring budget. So, paying lots for materials was out. For the frame, I recycled some European pine bearers that had been shipped to NZ as packing material for some large machines (this is low grade core material, which is why you’ll notice fairly extensive cracking in later photos).

Because this is such a low grade material, I don’t want to rely on it for strength, so I scrounged some scrap angle iron, steel flat bar, and threaded rod to reinforce the wood with. The wood still provides a nice aesthetic and good “spring” in the press, but the main loading is all on the steel. Bolts were scavenged from the same place as the wood.

For the basket and drain I selected NZ Macrocarpa that I can get in a rough sawn clear grade from a local mill, then do the ripping / dressing myself. I cut a corner on the basket construction and used aluminium flat bar for the hoops instead of stainless, because that’s what I had. Hopefully I don’t pay for that later! The drain tray is stainless sheet from a scrap dealer, with a bit of tig work done by a friend and a stub of stainless pipe sawn off an old keg stem. I had to actually buy stainless screws (Shock, horror) and some worktop oil for fixing and sealing the basket and drain. The basket is lined with muslin cloth during pressing, which cost 20 bucks for about 70m.

I wasn’t going to piss around making those mincy little presses you see in homebrew shop that take 5 – 20L of pulp per press cycle, so I settled on an 80L press capacity. I figure that it can be reasonably efficient with a 50L pulp load, which will be ideal for other home brewers to use to get their 30L fermenter full, and also will be time effective for the odd crazy person like me who needs reasonable production out of it. It needed to be able to fit in my car once done with minimal deconstruction, be set up in a standard stud height garage, while the drain needed to be at least high enough for a 30l fermenter, and preferably high enough for my 75l fermenters too.

I apologise in advance for having made no plans whatsoever for others to follow, but I figure there are plans out there for those that need them. This is just my made up as I go along design.

Building

The basket

I decided to start with the basket. I used a panel saw and a 4-sider to make my staves out of rough sawn boards.

Quite nice grain in there under all the surface damage from the mill.

To the four sider:

This thing is pretty sweet. It’s a little baby foursider for joinery shops and so on. It projects the spindle settings out onto the workpiece with lasers. Everything is better with lasers. And this is much less scary to use than a jointer + thicknesser.

I processed a bit extra while I was at this for making the drain. More on that later.

Right, so I’ve got all my staves, dressed and squared, so it’s time to oil them.

I did one coat an evening for a couple of days.

I drilled out a good spacing on my flat bars (soon to be hoops) with a drill press, aiming to have about 10mm between the staves at the inside of the basket after forming it into a cylinder. I taped the bars together for this so they’d all be dead on, no crooked staves.

With the hoops accurately drilled, I could start assembling the basket. The screws are stainless self tappers.

I left plenty of overlap, for weldng the bands after shaping, then set about to making it round. I found that ratchet load binders worked well for this, combined with a bit of brute force.

I dismantled the basket, then the hoops were TIG welded by a friend…

And given a brush finish,

Then the whole thing was put back together again.

Basket done. It’s not a perfect cylinder but close enough. I reckon a few press cycles should sort that out anyway.

The Drain

The drain is what the basket sits on, and what channels the juice into the output vessel. Because I was building a reasonably large basket, I wasn’t happy with the idea of the press load sitting directly flat stainless pan – it would be hard for the juice to flow out.

Right?

Right.

Having decided that this was a problem (with little-to-no research), I set about making a solution out of wood. I needed a slatted tray to press against, but juice needed to be free to flow out between the slats. This is the [potentially over complicated and fragile] answer I came up with.

I took some of the same material that I made the staves with, and thinned it down a touch with the foursider – no reason to take up more height than is absolutely necessary here, because it’ll just make the overall height taller and more awkward. Then I thinned down a few lengths even more, and went to the band saw and started cross cutting:

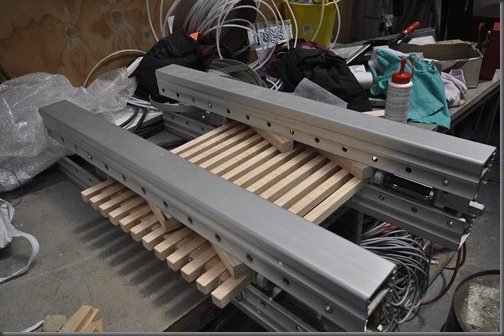

The idea mocked up, sitting upside down in the stainless drain pan (which has been tig welded by this point):

Then I got to gluing and clamping, which was a bit tedious. I have these neat clamps to use though which clamp across and down at the same time, that made it easier. By gluing it upside down I was able to get a roughly level top surface (bottom surface in the clamps). The slats will be in compression (i.e. completely supported) during operation, and the shear stress on each glue joint should (he says, with absolutely nothing to back it up other than the fact that I’ve done it now) be low enough for the glue to hold the spacers in place. I used a structural grade PVA, it’s MSDS checked out alright for this application, but do check out glues before using them in potential contact with food / drink.

Much nicer than sash clamps, But I did need to use some wood as spacers as they're designed for thicker workpieces than this.

I left the work clamped overnight, and in the morning…

It worked! A bit of orbital sanding on the top to sort out the glue squeeze out, and the same oil as the basket, and it was good to go.

Press Board

I found an old 8 ton hydraulic jack to use for the press power. But you still need a press board to act like a piston head. I decided that I would rip up some more macrocarpa, joint it with a Hoffman jointer (dovetail keys) and then cross laminate it so I still get good strength out at the edges.

So, back to the panel saw to cut the main boards, and measure out my hoffman joint locations…

… And then over to the hoffman jointer…

This is how they work:

Having routed all the joints I started gluing and jointing:

And then the whole lot was clamped up overnight.

With got the main boards jointed and glued, it was time to cross laminate a layer across it. In an ideal world I’d laminate a layer above and a layer below, to balance the compression and tension in the grain across opposite sides, but I ran out of wood…

I ran the timber through a thicknesser to get it even, and also ran the previous lamination through at the same time:

Then got out the cool clamps again, glued and clamped the layers together. Because the new, unlaminated layer is wider than the other layer, I can do both with grain and cross grain lamination at the same time:

The previous lamination goes on, cross grain. I've placed it with the hoffman keys in the center to keep them out of sight.

After the work had been clamped overnight, I chucked it on a CNC router and set fire to the machine by using the wrong cutter milled out the cross laminated board into a circle, sized to have about 5mm clearance inside the basket.

With a bit of sanding and a coat or 3 of worktop oil to seal, the press plate was done, although I find it hard to resist putting it in my kitchen and using it as a chopping board.

The Press Frame

So, with all the hard stuff done, I just needed to build a frame to hold it all together! I have to apologise about the standard of photos for this section, my DSLR was elsewhere for this section. Good thing it’s the more boring part.

I cut all my pine beams down on the panel saw. They are so hopeless twisted from drying too fast that I didn’t even bother trying to straighten them on the foursider – I would have lost too much wood.

I misused the panel saw to save me some work with the bandsaw (I would have had to assemble one) – bit naughty, don’t try this at home, etc. I was wanting to make a couple of half-lap joints for the drain bearers and a kind of bastardised tenon for the feet.

The drain bearers - the fit is good enough that with the steel reinforcing in place, they stay on with friction alone.

I cut up, cleaned, welded, and etch primed my steel reinforcing to take the load under the drain bearers (the cross members in the above image), and above and below the press bar (below basically just to stop the jack damaging the wood, top to take most of the stain). I used some offcuts of the angle iron as fixtures to attach the press bar to the uprights.

From the above image I’m sure you can guess how the drain bearers were supported, but the press bar assembly might be a bit cryptic so this should explain it:

There is steel flat bar both above and below the press bar, and angle iron masquerading as a fixture on top to screw through into the uprights. I used flat bar here because I want this to have a bit of movement in it, so that I can load up pressure on it and have to pump the jack less frequently.

I drilled the steel so I could run threaded steel rods between the press bar and the drain bearers – this is of course where most of the pressing force is loading, so it’s nice to have all of this load going through metal rather than dodgy recycled wood.

I hit a minor problem when I found that my threaded rods were not quite long enough, so rather than buy some more, I made up a couple of little connecters on the lathe:

Then I cut one rod to size the hard way:

After which I kicked myself, and cut the second one the easy way:

In order to get the whole thing just a bit more attractive, I rounded the edges of the wooden sections with a corner rounding router bit and a router table…

The frame wood all got oiled with a product called CD50…

And I put the whole thing together:

It lies flat in my car with the feet taken off, so I got it home and started using it. Note the use of a bit of plastic food wrap around the basket to prevent any squirts from making a mess. I wouldn’t bother if I was outside, I just don’t want ants and wild apple ferments where I brew…

It works great! We’re getting 70%+ extraction by weight on the thawed pulp. We could probably go higher but the apples are free and plentiful, so we aren’t using too much time going for the last 5%. The first 25l of juice literally falls out of the press without even engaging the jack.

I don’t really have a fair measure of how long a press cycle takes, as I’ve been drinking and chatting etc every time we’ve used it so far, but it’s probably about 20 minutes if you were paying attention, maybe a bit longer. One thing I can say for sure is that it takes a lot longer if you haven’t used pectinase, and the extraction is much worse.

The first load of cider is going into a 220L ex-wine barrel to age til next summer, and the remainder will be a few experiments with French style cider and berry ciders, with the balance to be fermented on the pulp and pressed post-fermentation for calvados – and maybe a fruit based neutral from absinth! I also want to experiment with using the pressed pulp (“cheese” is the correct term I’m told) with dextrose added to see if I can’t make a grappa-like spirit out of apple waste. I’ve got a 50L carboy that is just begging to be used for “keeving” the french cider.

Cheers.

0 Responses to “Building a cider press”